But those plans changed when we got a call from the husband's uncle, Perry. It was cherry picking time, and so we spent the weekend at Perry's orchard about 20 minutes from our house, helping out with the annual harvest.

The whole process is really quite a production.

First, the husband headed out into the orchard with a team of pickers. His view out there was rather spectacular.

Perry grows two kinds of cherries: black tartarian sweet cherries and montmorency cherries, the tart little suckers that make their living in jams and pies. We were there to harvest the montmorency cherries, which I think are one of the most beautiful trees grown in the area.

The cherries are the most vibrant light red color. It almost looks like they glow next to the smooth green leaves of the tree.

The husband was in charge of driving the tractor pulling a flatbead trailer with a large metal bin full of cold water. As the pickers filled each carton, they dumped it in the water in the bin, and the husband used a strainer to pull out any floating leaves or stems.

Once the bin was full (about 1,200* pounds of cherries), the husband brought the bin back to the processing area where he placed it up on a platform. (Have you ever heard that country-western song, "She thinks my tractor's sexy"? Now you know why that song was written...)

*Editor's note: Updated 7/16/10. The editor of the editor [the husband] just called from work to inform me that my original number of 200 pounds of cherries, based on my recollection of our conversations, was woefully inaccurate. He wants to make sure all of you know that he wasn't so silly as to use a big 'ol forklift just to move around a few hundred pounds of stuff. :)

From there, the cherries were dumped into a large holding tank with ice cold water where they were washed and left to cool down to the desired temperature. Cooling them down helps to firm the flesh of the cherry, which makes it easier to pit them.

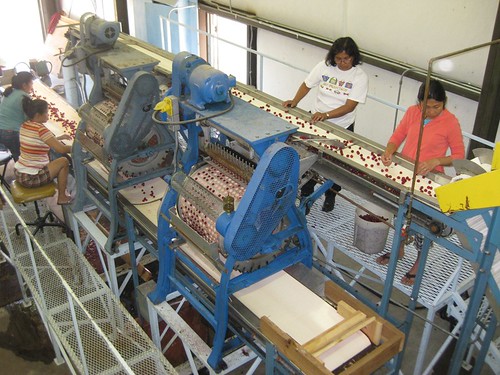

Once the cherries were cooled enough, they were slowly released from the holding tank and then transported up an escalator that drained the water. This is where I was positioned on one of the days. The job here is to pull out as many stems, leaves, twigs, and defective cherries as you possibly can as they whiz by you on the conveyor belt.

It can be tedious work, but in a way it was kind of fun. I have a somewhat competitive personality, so I rather enjoyed the challenge of trying to fill my bucket of gunk higher than the other people on the assembly line!

Once the escalator reached the top, the cherries were dumped onto another conveyor belt where two or three people were positioned to continue to pull out as many stems and bad cherries as they could.

As the cherries moved down the line they were sent into one of two pitting machines. If you've ever had to pit cherries by hand, you would be in awe of the pitters. Each cherry is deposited into a rubber cup with a small hole in the bottom, and a large metal rod comes down and pushes the pit out of the cherry and through the hole in the cup.

The pitted cherries are dumped onto a lower conveyor belt, where more people are stationed to pick out any remaining bits of stems or bad cherries, and to look for the occasional stray pit that escaped the pitting machine.

The pits are carried by a pipe to a trailer outside of the building where they are deposited into one awe-inspiring large pile of pits.

That's a lot of pits.

The cherries continue down the assembly line until they are funneled into a waiting container. The containers sit on a scale that is adjusted for a particular weight. Once that weight is reached, the funnel closes so that the full container can be replaced with a new container. Shown here are 4-pound containers. We also filled 8- and 25-pound containers, as well as a few bulk containers of several hundred pounds of cherries.

The very convenient thing about this kind of cherry is that they are immediately placed into the freezer, so the orchard owner isn't under pressure to sell them quickly after they're picked.

Over the course of both days, we processed approximately 12,200 pounds of cherries. Several hundred pounds of cherries went straight to a local winery to be made into cherry wine. The 25-pound containers are often sold to local bakeries, and the 8-pound containers are often sold to individuals who really like to bake or can, or to retailers as far away as Denver who re-sell them.

As partial payment for my hours of service, I walked away with several of the 4-pound containers, which are a more manageable size for moderately-ambitious canning and baking projects. They're currently sitting in my freezer, awaiting their fate.

Now I guess it's time to dust off all my canning jars...

Wow, that pile is the pits!

ReplyDelete(I'm sorry.)

Mmm, cherry pie.

That sounds like a Bilyeu style anniversary celebration if I ever heard one! Super-sized!

ReplyDelete